From ‘Sensing’ to ‘Sensemaking’

Combining reliable technology with superior field knowledge, Yokogawa has insights into the lifecycle of the device that provides added value to the user.

YTA Total Insight offers valuable information throughout the devices’ lifecycle.

- Sensing Selection : Engineering and Procurement

Simple lineup and a wide range of international approvals help the customer select the right product.

- Easy Installation : Configuration and Commissioning

Various ways of configuring devices contribute to reduced installation and configuration time.

- Rich Information : Operation and Observation

Valuable diagnostic information leads to improved process efficiency.

- Expert Solution: Maintenance and Service

Providing timely maintenance information contributes to reduced maintenance cost.

- Sensing Selection: Engineering and Procurement

Simple lineup and a wide range of international approvals help the customer select the right product.

The safety of personnel is equally as important as plant availability, throughput, and profitability. For these reasons Yokogawa believes safety should never be an option, it should be a standard feature in all modern process automation & control equipment. The YTA610 has been designed and built by this philosophy.

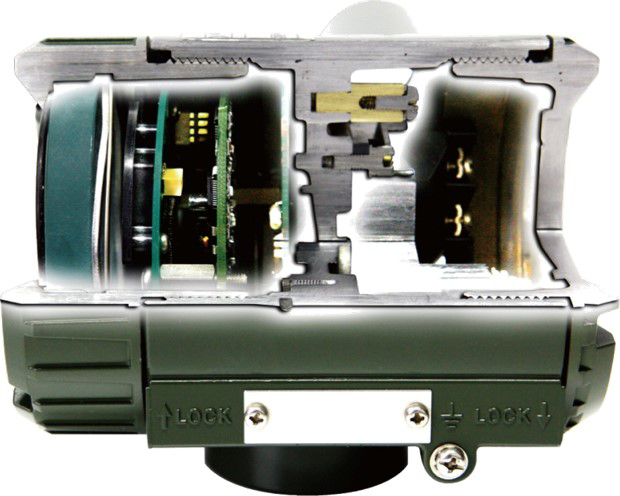

Rugged Construction

Today’s temperature applications can be located in very harsh environments; Yokogawa’s temperature transmitters are engineered to endure the severe conditions with a dual compartment housing design made from either low copper aluminum or stainless steel. The dual compartment design isolates the field wiring terminals from the electronics.

Exida® IEC 61508 Certification

The Yokogawa YTA610 series temperature transmitters are designed and certified to IEC61508:2010 Parts 1 through 7 and IEC61511:2004 Parts 1 through 3. It is approved for single transmitter use in SIL 2 safety applications and dual transmitter use in SIL 3 safety applications with no unique option required. With Yokogawa YTA610 temperature transmitters, no longer will you have to maintain two separate inventories - one for production applications and one for safety applications. How much will that save your company?

Worldwide Approvals

With the rapid globalization of markets, numerous international standards and approvals are becoming necessary. The YTA610 has acquired various international certifications including FM, CSA, ATEX, IECEx, INMETRO, KOSHA, EAC, and NEPSI.

Universal Inputs

In addition to measuring temperature with various RTDs and thermocouples, the YTA610/YTA710 can be used to convert DC voltage and resistance into an analog 4 to 20 mA output. There is a wide range of devices that can be used to supply a resistance or voltage input

- Easy Installation: Configuration and Commissioning

Various ways of configuring devices contribute to reduced installation and configuration time.

Local Parameter Setting (LPS)

Basic parameters can be set quickly on-site with the LPS configuration buttons, located on the display, without the need for a Hand Held Communicator (HHC) or additional configuration tools.

Configuration Using FieldMate

FieldMate is a tool for adjusting and configuring instruments. Instrument maintenance, management, and even replacement can be performed with easily understood intuitive screens. With the proper modem, FieldMate can communicate with Hart®, FOUNDATION™ Fieldbus, Profibus, Modbus, or ISA100 instruments.

Sensor Matching (Optional)

Although all RTD sensors follow an overall standard resistance curve, each sensor, because of the manufacturing process or slight variations in material makeup, have a unique resistance output curve. The difference between the ‘ideal’ standard curve and sensor’s actual curve will cause errors in measurement. For applications with a high accuracy requirement, temperature sensor manufacturers can supply sensor-specific information to define the individual resistance output. Sensor matching is an optional function available on the YTA610/YTA710 for RTD sensor that can use the sensor manufacturer’s sensor-specific information (known as Callendar-Van Dusen coefficients) to increase the accuracy of the measurement.

Custom Thermocouple User Table

The YTA610/YTA710 offers a range of preprogrammed thermocouple inputs; but, if the input Thermocouple being used is not one of the preprogrammed and the temperature-to-EMF data is available for that sensor, the YTA610/YTA710 uses the custom table to determine the temperature based on the thermocouple EMF input value via FieldMate.

- Rich Information: Operation and Observation

Valuable diagnostic information leads to improved process efficiency.

Sensor Failure

This diagnostic detects any disconnection of a sensor. When current is applied, and the resistance of a sensor is above a determined threshold, the transmitter outputs a sensor failure alarm. The diagnostic is available for TC, RTD, mV and resistance inputs. The alarm threshold is determined by the type of input. For a YTA610 that has two sensor inputs, different alarm codes are generated to identify which sensor has failed.

Terminal Block Failure

This diagnostic detects any disconnection at the cold junction compensation (CJC) point on the terminal block. When the function detects a resistance of the CJC above the pre-determined threshold, the transmitter outputs a terminal block failure alarm. The diagnostic is available for TC.

TC/mV Sensor Diagnostic

This diagnostic measures line resistance of the measuring loop. This information is used for preventive maintenance. This diagnostic is related to Namur NE89 recommendations.

Sensor Drift Diagnostic

On a YTA610 with two sensors, this diagnostic monitors the difference between the two sensors. When the difference becomes larger than an end user set threshold, the transmitter outputs a sensor drift alarm. This function is available for TC and RTD inputs.

Namur NE107

All device alarms are classified into the four categories (“Failure,” “Function Check,” “Out of Specification,” and “Maintenance Required”) defined by the NAMUR NE107 recommendations. These alarms are displayed on the asset management system in the appropriate category, enabling the operator to recognize the device status and take the necessary corrective action.

- Expert Solution: Maintenance and Service

Providing timely maintenance information contributes to reduced maintenance cost.

Service Log

Alarms detected by the instrument are stored in internal memory along with runtime information. Troubleshooting can be performed quickly by checking the log.

- Alarm Log

- Max / Min temperature sensor value

- Max / Min ambient temperature value

- Operating Time

Device Lifecycle Management

The newly developed Device Lifecycle Management service helps to minimize the amount of manual work that must be performed and improves the management of devices information. This service makes it easy to register, view, and manage information on instruments that is useful for maintenance work and helps customers to improve the efficiency of plant maintenance work and the quality of data management. Through solutions such as this Device Lifecycle Management service, Yokogawa will provide its customers with the support they need to ensure the optimal control of their plant assets.

Detachable Lightning Protector (Optional)

The YTA610/YTA710 offers an optional lightning protector that is connected directly to the multi-level terminal block. The design allows the lightning protector to be easily added or replaced in the field.

Data Transfer

Yokogawa’s FieldMate - Versatile Device Management Wizard can be used to program the same configuration into multiple devices using the data transfer function, reducing the total device configuration time.

Yokogawa temperature transmitter can use RTDs or thermocouple sensors from any number of suppliers

Brochures

Instruction Manuals